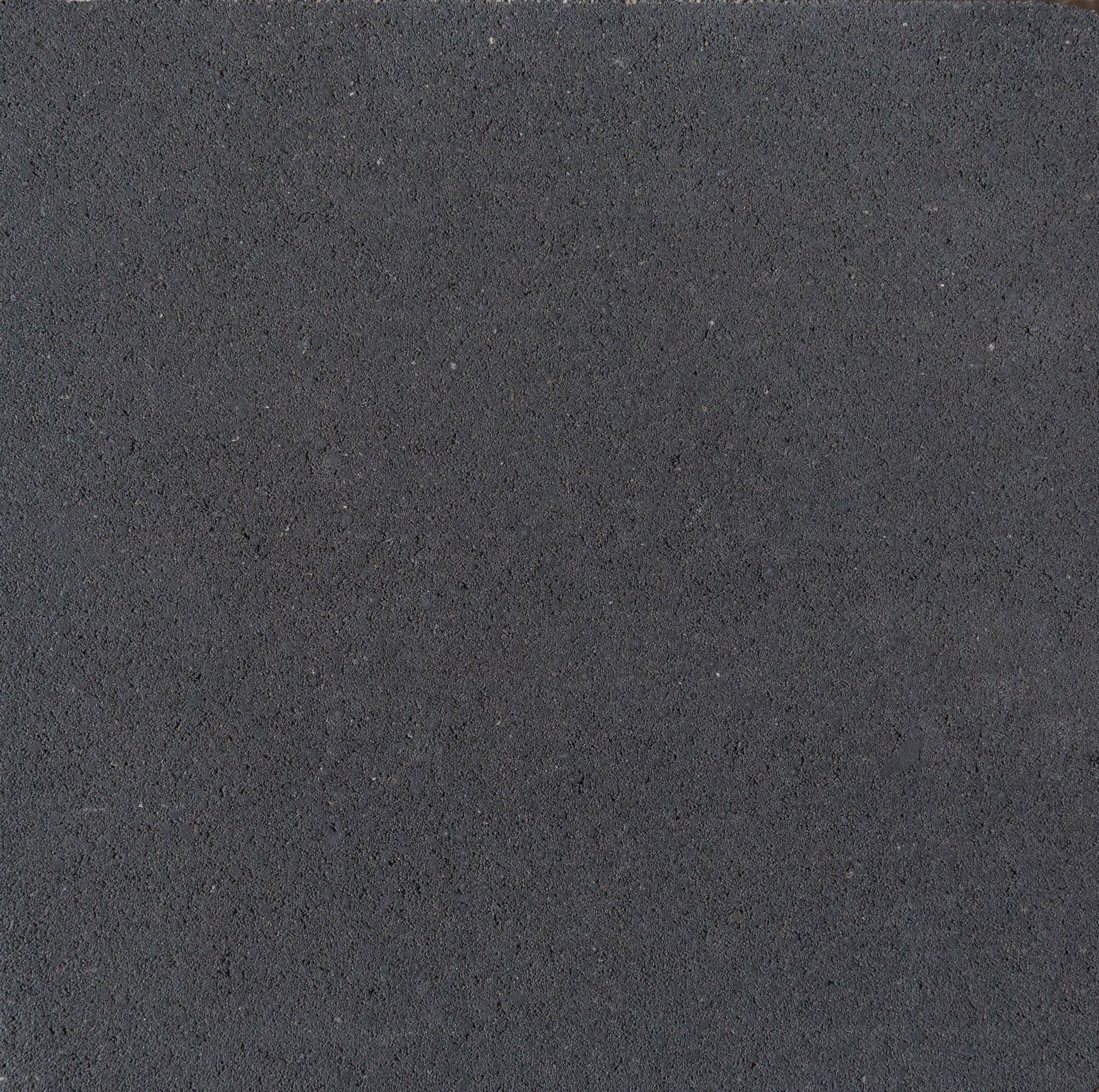

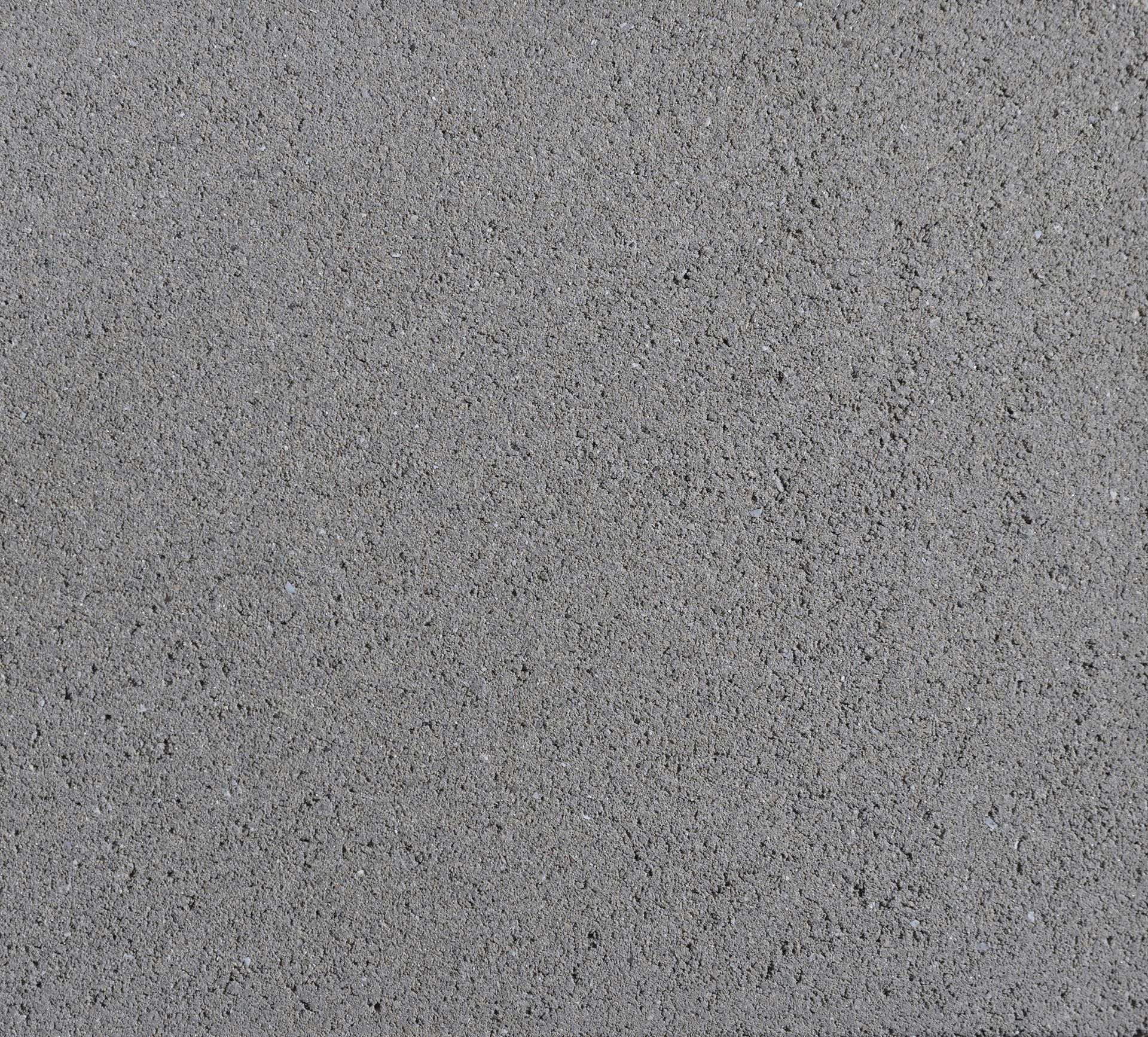

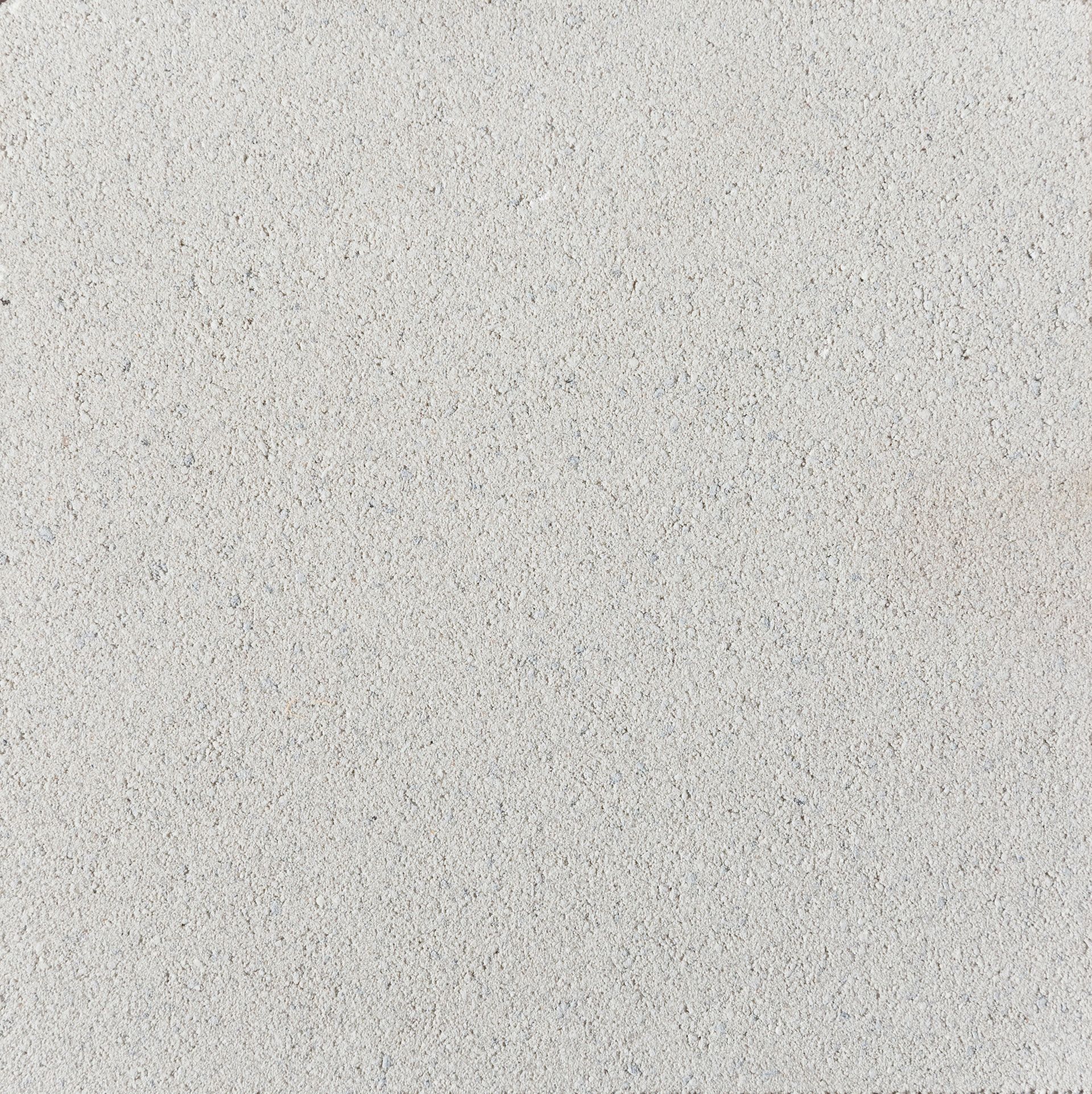

Our Colors

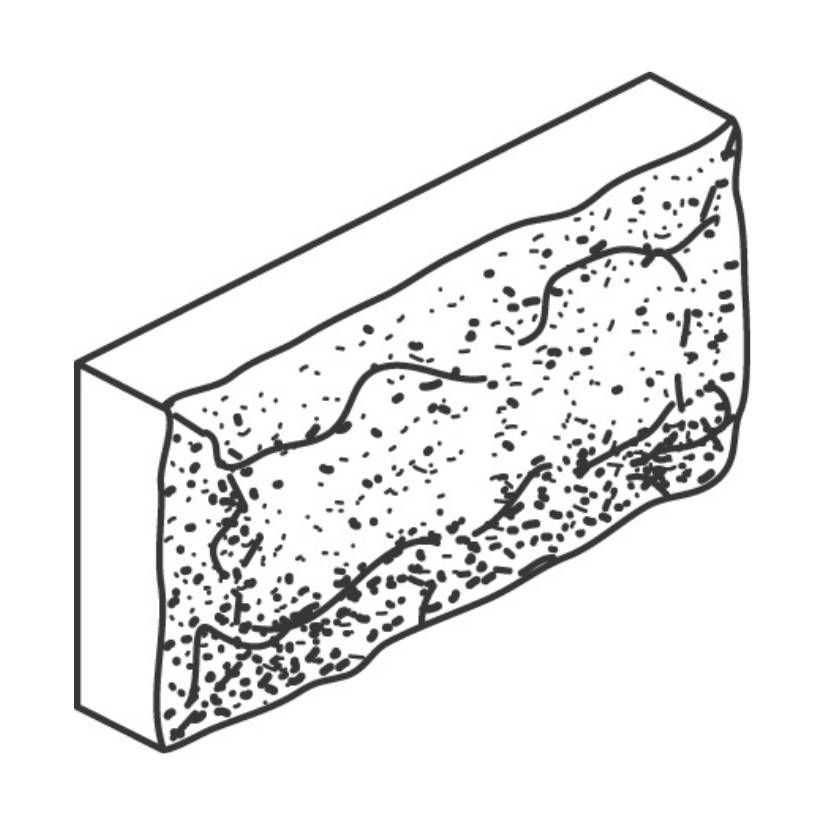

Custom Color Matching

At Reading Rock, we excel in custom color matching, ensuring our RockCast blends seamlessly with existing materials. Unlimited color options available that are sure to meet any design requirement.

Design with Confidence

Seamless Integration

RockCast’s custom color matching ensures a perfect fit with existing materials.

Unlimited Color Options

Choose from a vast range of hues or create a custom blend.

Advanced Manufacturing

Consistent, high-quality color production for every project.

Architectural Versatility

Designed to complement diverse styles and materials.

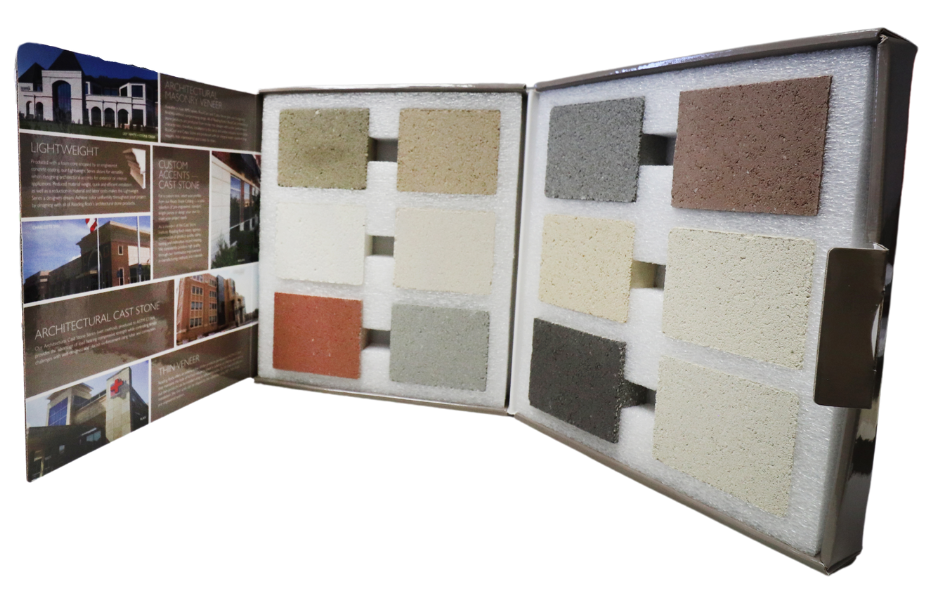

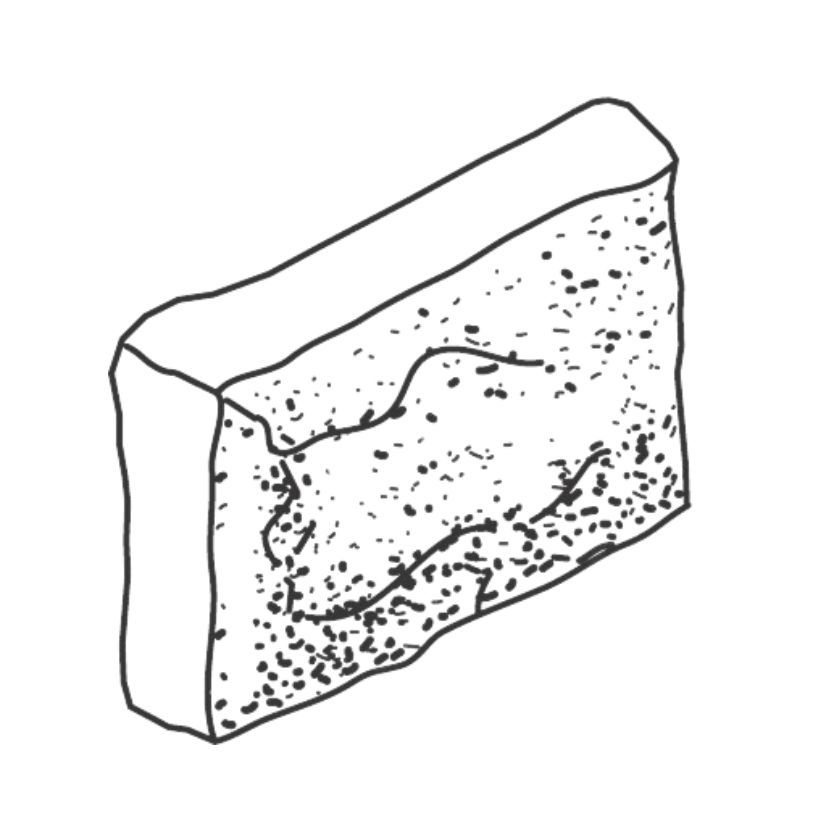

Request Your Color Kit Today!

Looking for dependable color options that make selection easy?

Our Color Kit features clean, standard monotone tones that deliver timeless style and reliable consistency.

Design with Confidence

See and feel our standard monotone color options in person—ensuring accurate selections that align with your design vision and client expectations.

Enhance Presentations & Client Meetings

The Color Kit is a professional, tangible tool to support concept boards, material presentations, and on-site consultations.

Informed Specifications

Make faster, more precise material selections backed by real samples—streamlining the specification and approval process.

Organized & Office-Ready

Compact, clean, and easy to store—an essential addition to your materials library or sample room.

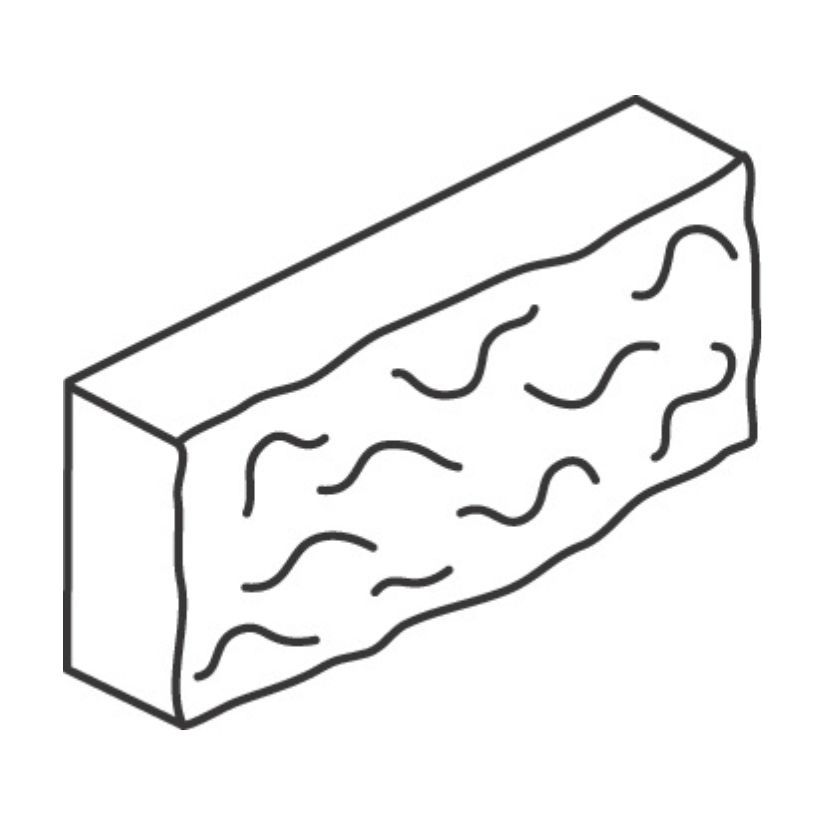

Our Process: Quality at Every Step

We don’t leave anything to chance. At Reading Rock, we control every step of the process to ensure top-quality products, fast turnaround, and reliable delivery.

Step 2:

Precision Manufacturing

From the careful selection of raw materials to the final product, our experienced team monitors every stage of production for consistency and durability.

All Reading Rock manufacturing facilities are certified by the NPCA, meeting the highest standards for plant facilities, production, and quality control procedures.

Our cast stone products undergo rigorous examination of product quality, safety, testing, and meticulous record-keeping certified by the Cast Stone Institute (CSI)

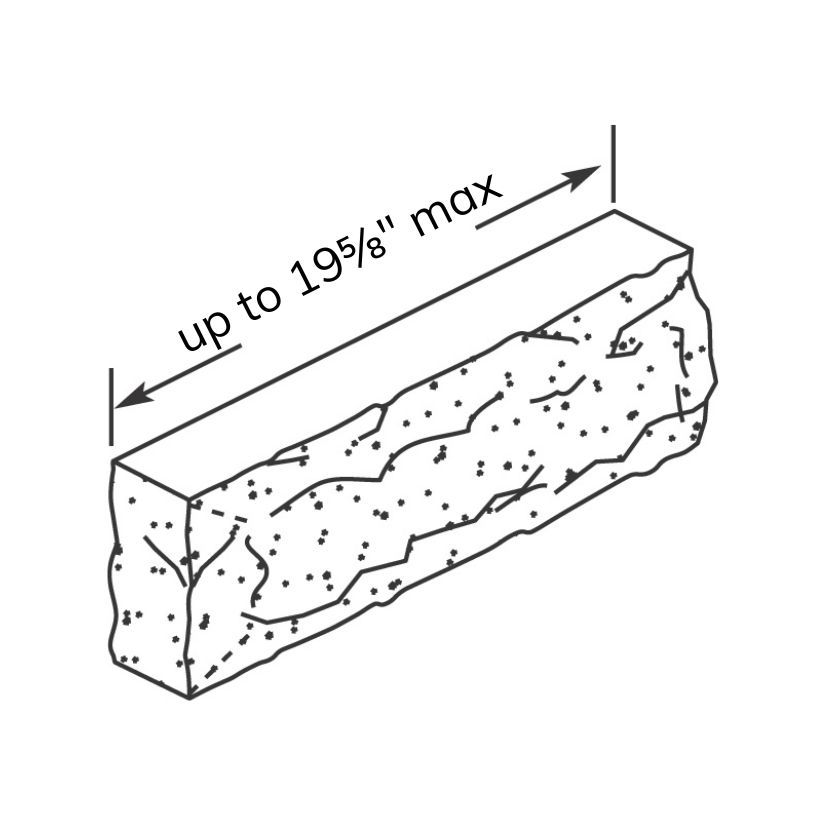

Guidelines and Specs

Need Help with Your Architectural Masonry Veneer Project?

Contact Us

Have questions about product details, ordering, or installation? Our team is here to assist you at every stage of your project. Whether you’re selecting the right textures and colors or need expert advice on design and application, we’re ready to help.